Guidance on sound data erasure routines

One fundamental aspect when considering the repurposing of technology is to ensure that data privacy and protection

requirements are observed to prevent an unwanted data breach. The reuse of devices with storage components requires a sound process for data sanitization. Moreover, the sanitization process for

flash-based memories can be hindered by the added complexity due to data management processes on a device.

Blancco Technology Group is leading the data security aspect of the project with the primary aim of identifying and

disseminating the processes required to enable secure disposal or repurposing of memory components. The guidance report aims to provide recommendations for different entities such as recyclers,

companies, governmental organizations and individuals on secure end of lifecycle actions for mobile storage technologies. Additionally, the guidance report gives recommendation to the memory OEMs

on actions to be taken to facilitate secure storage sanitization. The report gives a deep overview of mobile and storage technologies, risks and threats of insecure media sanitization as well as present the analysis on various options for data destruction.

sustainablySMART session “Smartphones: Repair, Remanufacturing and Reuse of Components” at CARE Innovation 2018

Following papers have been presented at the CARE Innovation, Vienna, November 26-29, 2018, and are documented in the conference proceeding:

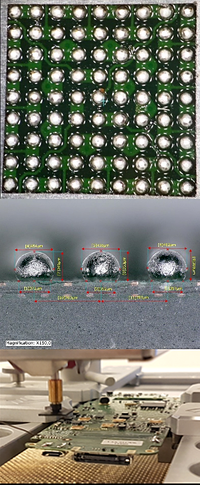

Remanufactured packaged semiconductors: Technology validation

A key strategy for a high-level reuse of semiconductors from smartphones and other mobile devices is a sound remanufacturing process for harvesting and reworking packaged components. The

reliability of these remanufactured integrated circuits needs to be validated to allow for a re-integration in new products. Only if the remanufactured components are not a weak spot in new

devices the full circular economy potential of semiconductor reuse can be explored.

sustainablySMART partner Semicon, supported by Tele- and Radio Research Institute (ITR), developed a remanufacturing technology of valuable semiconductor components de-soldered from used mobile

products, which was validated in laboratory and industrial investigations. Components in Ball Grid Array (BGA) housing such as flash memories, processors, microcontrollers etc. were selected for

the remanufacturing process.

After all laboratory and industrial trials a technique based on automatic solder spheres placing on components pads and flux application was selected as the most promising technique for

remanufacturing of valuable semiconductor components. The technology verified independently by partners ITR and Speech in lab and industrial environment confirmed good quality and high

reliability of semiconductor components after remanufacturing process.

The remanufactured components using the technique T3E3 seem to be more reliable than

it was expected by the project team. This issue will be the subject of further investigation

in upcoming project activities.

Reuse of desoldered BGA packages demonstrated

The experiments carried out proved that the use of recovered BGA chips is feasible. Semicon demonstrated the assembly of the

boards with industrial equipment. The designed demonstrator devices were functional even after harsh climatic tests. The processes demonstrate implementation of a circular economy approach,

advancing the recovery of functional semi-conductor packages, thus saving raw materials and replacing potentially newly manufactured semiconductor components.

Collaborative disassembly robot: Technology demonstration

ProAutomation has developed a collaborative robot system. The concept implies that the mobile phone disassembly is

performed by a robot, while certain complex tasks such as unscrewing PCB screws is performed by operators.

To this end, the collaborative robot SAWYER has been employed.

Recycling options for Tantalum and Gallium

The sustainablySMART projects explores the option to separate tantalum-rich, gallium-rich and tungsten-rich components from disassembled smartphones as these metals are lost in conventional electronics waste recycling processes. Tungsten has been chosen as a subject of these investigations on top of the other two metals, as it is one of the potential conflict minerals and therefore there is a particular political and industry interest in this material. Components, where most of the 3 metals are found are tantalum capacitors, high-frequency semiconductor modules (containing GaAs chips) and vibration motors with tungsten as a counterweight. Whereas recycling processes for tantalum capacitors are in place for post-industrial scrap and now increasingly also for post-consumer scrap, there is no such technology available for gallium (where the recycling loops end at the level of GaAs wafer scrap) and for tungsten the other contained materials in vibration motors hinder recycling and a pre-treatment process for liberating tungsten would be required. The separation of all three components can be integrated in the automated disassembly process (desoldering of tantalum capacitors and GaAs chip packages along with semiconductor packages for reuse; mechanical removal of the vibration motor from a backside cavity in the LCD frame). A technology concept and application is achieved within this project. The contained material value however is extremely low in the case of gallium, and enough primary material can be made easily available as a by-product of bauxite processing, that there is no case in recovering gallium from complex electronics components. Similarly the value of tantalum found on mainboards of smartphones is in the sub-cent region and economic viability of the extra separation step is questionable. The fact that tantalum is a potential conflict mineral and the much more limited resources compared to gallium and also tungsten might make tantalum capacitors a better candidate for recycling, if this corresponds with company policy. The amount and raw material value of tungsten (maximum 1,8 Euro-Cents per smartphone) lead to the highest priority of all three metals for exploring separation and dedicated recycling. Compared with other metals investigated in this project the theoretical value of tungsten comes close to that of neodymium from loudspeakers, but is much lower than that of the cobalt in the batteries.